ʻO ka mīkini CNC ma nā ʻāpana keleawe no ka lāʻau lapaʻau

ʻO ka wehewehe ʻana o nā ʻāpana mīkini CNC me nā mea keleawe

ʻO ke keleawe he nonmagnetic a ʻaʻole hoʻi i hoʻāla ʻia, kūpono ia no ka hoʻohana ʻana i nā lāʻau lapaʻau i ʻike ʻia i nā au uila a i ʻole nā māla kiʻekiʻe. ʻO ke keleawe kekahi i ka corrosion-resistant, a he mea maikaʻi loa ia no nā mea lapaʻau i ʻike ʻia i ka wai a i ʻole nā wai ʻē aʻe. ʻO ka mīkini CNC i ke keleawe e hiki ai ke hana i nā ʻāpana paʻakikī, paʻakikī me kahi kiʻekiʻe o ka pololei a me ka pololei. Hiki ke hana ʻia nā ʻāpana keleawe i nā kikoʻī kikoʻī a me nā hoʻomanawanui, e hōʻoia ana i ka palekana a me ka maikaʻi o nā mea lapaʻau.

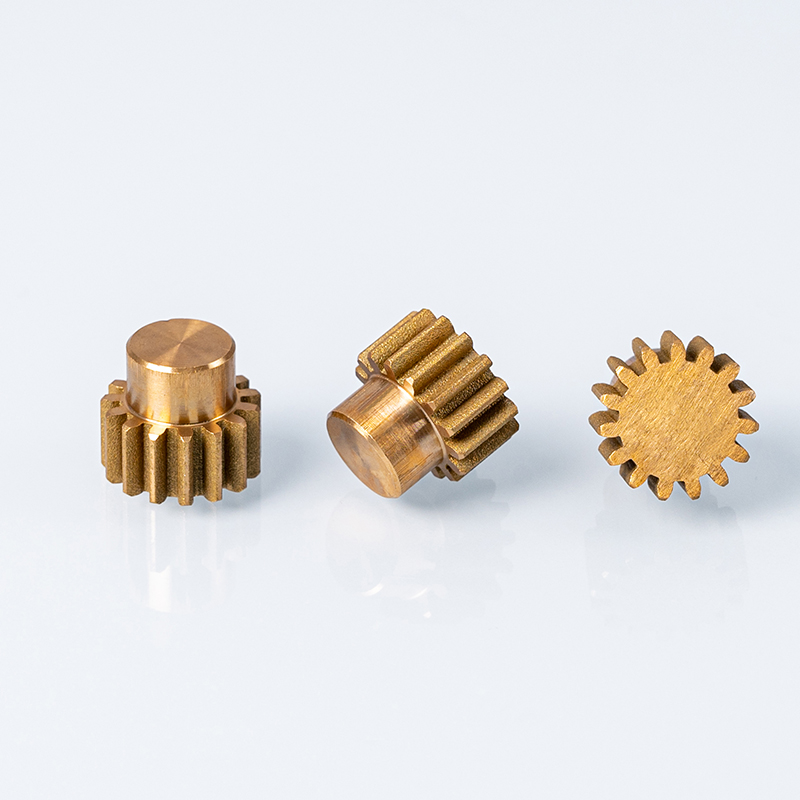

1. Mea keleawe: C110 (99.9% Copper)

2. Kaʻina Hana: CNC Machining

3. Hoʻomanawanui: +/-0.01mm

4. Hoʻopau: Kūlohelohe 5. Hoʻohana: Hoʻohana ʻia i ka uila, uila, kukui a me nā ʻoihana ʻē aʻe.

ʻO ka pōmaikaʻi o ka CNC machining Copper

Hāʻawi ka CNC machining copper i nā pono he nui, e like me ke kiʻekiʻe kiʻekiʻe a me ka pololei, ka maikaʻi o ka ikaika-i-kaumaha ratio, maikaʻi thermal a me ka uila conductivity, hoʻonui corrosion kū'ē i hoʻohālikelike ʻia me nā metala ʻē aʻe, dimensional stability ma luna o kahi ākea ākea, hoʻemi ʻia ka manawa mīkini ma muli o kona malleability a me ka maʻalahi o ka machinability.

1. ʻOi aku ka ikaika a me ka lōʻihi - He mea paʻa loa ke keleawe a hiki iā ia ke pale i nā wela kiʻekiʻe, kaomi a me ka lole. ʻO kēia ka mea i koho maikaʻi loa no nā noi mīkini CNC, no ka mea hiki ke hoʻohana ʻia i nā ʻano like ʻole o nā noi a hiki ke pale aku i nā koʻikoʻi o ka repetitive, nā hana machining kiʻekiʻe.

2. ʻOi aku ka maikaʻi o ka thermal conductivity - ʻO ke keleawe maikaʻi loa o ka hoʻoheheʻe ʻana i ka wela he mea kūpono ia no nā noi mīkini CNC e koi ana i ka ʻoki pololei ʻana a me nā hana wili. ʻO kēia ka mea e hōʻoiaʻiʻo ai e loaʻa i ka huahana i hoʻopau ʻia ka pae kiʻekiʻe o ka pololei a me ka pololei.

3. ʻO ka conductivity uila kiʻekiʻe - ʻO kēia hiʻohiʻona e hana i ke keleawe i mea kūpono no nā hana machining CNC e koi ana i nā wili uila a i ʻole nā mea.

4. ʻO ke kumu kūʻai - ʻoi aku ka liʻiliʻi o ke keleawe ma mua o nā metala ʻē aʻe, e lilo ia i mea koho maikaʻi loa no nā papahana machining CNC e pono ai ka nui o nā ʻāpana a i ʻole nā mea.

5. Maʻalahi e hana pū me - He mea maʻalahi ke keleawe e hana pū me, hiki ke hana wikiwiki a me ka pololei.

Pehea ke keleawe ma nā ʻāpana mīkini CNC

ʻO ka CNC machining copper parts e pili ana i ka hoʻohana ʻana i nā mea hana ʻoki pololei e like me nā wili hope e wehe i nā mea mai ka mea hana e like me ke ala i hoʻonohonoho ʻia. Hana ʻia ka hoʻonohonoho ʻana no ka mīkini CNC ma o ka polokalamu kamepiula-aided design (CAD) a laila hoʻololi ʻia i ka mīkini ma o ka code G, e hiki ai iā ia ke hoʻoponopono i kēlā me kēia neʻe. Hiki ke wili ʻia nā ʻāpana keleawe, wili ʻia a huli ʻia paha ma muli o ka noi. Hoʻohana pinepine ʻia nā wai hana metala i nā kaʻina hana machining CNC, ʻoiai ke hana nei i nā metala paʻakikī e like me ke keleawe e koi ai i ka lubrication hou.

ʻO ka CNC machining copper parts he kaʻina hana machining o ka hoʻohana ʻana i nā mīkini helu helu kamepiula (CNC) e hana i nā mea keleawe. Hoʻohana ʻia ke keleawe i nā ʻano hana CNC me ka prototyping, molds, fixtures, a me nā ʻāpana hoʻohana hope.

Pono ka CNC machining copper i ka hoʻohana ʻana i nā polokalamu kūikawā a me nā mīkini CNC i hoʻolako ʻia me nā mea hana kūpono e ʻoki pono ai a hoʻohālikelike i ka mea. Hoʻomaka ka hana ma ka hana ʻana i kahi hiʻohiʻona 3D o ka ʻāpana i makemake ʻia i kahi papahana CAD. A laila hoʻololi ʻia ke ʻano 3D i kahi ala mea hana, ʻo ia kahi hoʻonohonoho o nā kuhikuhi e hoʻolālā i ka mīkini CNC e hana i ke ʻano i makemake ʻia.

Hoʻokomo ʻia ka mīkini CNC me nā mea hana kūpono, e like me nā wili hope a me nā drill bits, a laila hoʻouka ʻia nā mea i loko o ka mīkini. A laila e mīkini ʻia ka mea e like me ke ala mea hana i hoʻolālā ʻia a hana ʻia ke ʻano i makemake ʻia. Ma hope o ka pau ʻana o ke kaʻina hana, nānā ʻia ka ʻāpana e hōʻoia i ka hoʻokō ʻana i nā kikoʻī. Inā pono, hoʻopau ʻia ka ʻāpana me nā ʻano hana like ʻole post-machining e like me ka buffing a me ka polishing.

He aha nā ʻāpana mīkini CNC hiki ke hoʻohana no ke keleawe

Hiki ke hoʻohana ʻia nā ʻāpana keleawe CNC machining no nā ʻano noi like ʻole, me nā ʻāpana uila a me nā mea hoʻohui, nā ʻāpana automotive kiʻekiʻe, nā ʻāpana aerospace, nā mea lapaʻau, nā hui mechanical paʻakikī a me nā mea hou aku. Hoʻopili pinepine ʻia nā ʻāpana mīkini Copper CNC me nā metala ʻē aʻe e hoʻomaikaʻi ai i ka conductivity a i ʻole ke pale ʻana.

Hiki ke hoʻohana ʻia nā ʻāpana keleawe CNC machining no nā ʻano noi like ʻole, me nā mea hoʻohui uila, nā hale kaʻa, nā mea hoʻololi wela, nā ʻāpana mana wai, nā mea hana, a me nā mea hoʻonaninani. He kūpono nā ʻāpana keleawe no ka mīkini CNC ma muli o kona kiʻekiʻe uila a me ka thermal conductivity, a me kāna kūpaʻa corrosion maikaʻi loa. Hiki ke hoʻohana ʻia ke keleawe machining CNC e hana i nā ʻano paʻakikī a me nā ʻāpana me nā ʻae pololei.

He aha ke ʻano o ka mālama ʻana i ka ʻili e kūpono i nā ʻāpana mīkini CNC o Copper

ʻO ka lāʻau lapaʻau kūpono loa no ka CNC machining copper parts he anodizing. ʻO ka anodizing kahi hana e pili ana i ka electro hana kemika i ka metala a hoʻokumu i kahi papa ʻokikene ma ka ʻili o ka mea e hoʻonui ai i ka pale ʻana a me ka pale corrosion. Hiki ke hoʻohana ʻia no ka hāʻawi ʻana i nā mea hoʻonaninani e like me nā kala ʻālohilohi, hoʻopau matte a i ʻole nā leo ʻālohilohi.

Hoʻohana pinepine ʻia nā ʻāpana keleawe me ka electroless nickel plating, anodizing, a me ka passivation e pale i ka ʻili mai ka ʻino a me ka ʻaʻahu. Hoʻohana ʻia kēia mau kaʻina hana e hoʻomaikaʻi i ka nani o ka ʻāpana.

Noi:

ʻOihana 3C, hoʻonani kukui, nā mea uila, nā ʻāpana kaʻa, nā ʻāpana lako, nā mea uila, nā mea lapaʻau, nā lako hana akamai, nā ʻāpana hoʻolei metala ʻē aʻe.